A PID Controller (Proportional-Integral-Derivative Controller) is a widely used control system mechanism that continuously calculates an error value and applies a correction based on proportional, integral, and derivative terms. It is commonly used in industrial automation, robotics, and process control systems.

1. How Does a PID Controller Work?

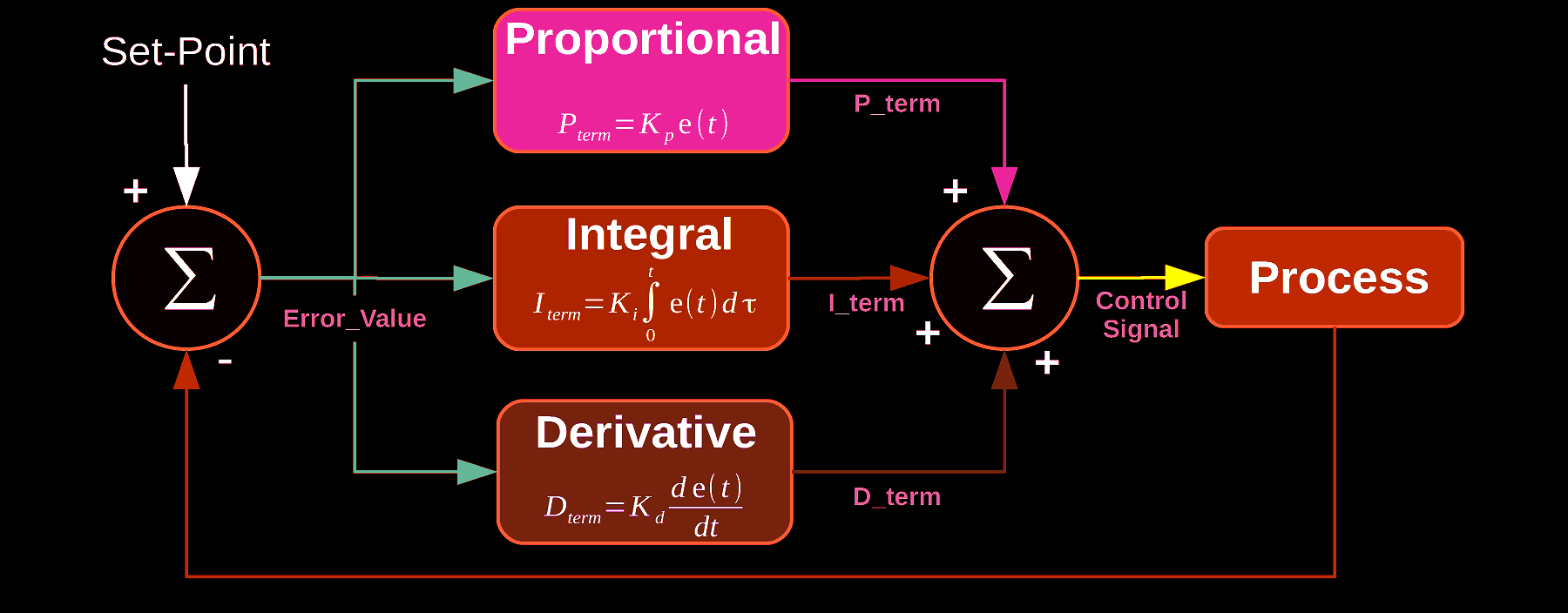

A PID controller works by minimizing the difference between a desired setpoint (SP) and the measured process variable (PV). This difference is called the error (e): e(t)=SP−PVe(t) = SP – PV

The controller then applies three corrective actions to adjust the system’s output:

- Proportional Control (P) – Reacts to the current error.

- Integral Control (I) – Reacts to the accumulated past error.

- Derivative Control (D) – Reacts to the rate of change of the error.

The control output is calculated as: u(t)=Kpe(t)+Ki∫e(t)dt+Kdddte(t)u(t) = K_p e(t) + K_i \int e(t) dt + K_d \frac{d}{dt} e(t)

Where:

- KpK_p = Proportional gain (determines response speed)

- KiK_i = Integral gain (eliminates steady-state error)

- KdK_d = Derivative gain (reduces overshoot and improves stability)

2. Breakdown of PID Components

(a) Proportional Control (P)

- Provides a correction proportional to the error.

- The larger the error, the stronger the correction.

- Improves response speed but does not eliminate steady-state error.

P=Kpe(t)P = K_p e(t)

Effect of Increasing KpK_p:

- Too low: Slow response.

- Too high: Oscillations or instability.

(b) Integral Control (I)

- Eliminates steady-state error by accumulating past errors.

- Slow response, but essential for precision.

I=Ki∫e(t)dtI = K_i \int e(t) dt

Effect of Increasing KiK_i:

- Too low: Residual error remains.

- Too high: Causes oscillations and overshoot.

(c) Derivative Control (D)

- Predicts future errors by measuring the rate of change.

- Improves stability and reduces overshoot.

D=Kdddte(t)D = K_d \frac{d}{dt} e(t)

Effect of Increasing KdK_d:

- Too low: System reacts too slowly.

- Too high: Causes excessive damping, reducing responsiveness.

3. PID Tuning: Adjusting Kp,Ki,KdK_p, K_i, K_d

Tuning a PID controller means selecting the right values for Kp,Ki,KdK_p, K_i, K_d to achieve optimal performance.

Tuning Methods

- Ziegler-Nichols Method (Experimental approach)

- Trial and Error (Manually adjusting parameters)

- Software-based Optimization (Using MATLAB, Simulink, or other tools)

- Auto-tuning Algorithms (Found in modern industrial controllers)

Effects of Tuning

| Parameter | Too Low | Too High |

|---|---|---|

| KpK_p (Proportional) | Slow response | Overshoot & oscillations |

| KiK_i (Integral) | Steady-state error | Excessive oscillations |

| KdK_d (Derivative) | Slower reaction | Unstable system |

4. Applications of PID Controllers

PID controllers are used in various industries for precise control of dynamic systems.

Industrial & Engineering Applications

- Temperature Control: Ovens, HVAC, water heaters

- Motor Speed Control: Robotics, CNC machines, electric vehicles

- Level Control: Water tanks, chemical reactors

- Pressure Control: Industrial manufacturing, power plants

- Position Control: Servo motors, robotic arms, drones

Everyday Applications

- Cruise Control: In cars to maintain constant speed

- Autopilot Systems: Aircraft flight control

- Drones & Robotics: Maintaining balance and movement

5. Types of PID Controllers

Depending on the application, PID controllers can be used in different configurations:

- P Controller: Uses only proportional control (fast but inaccurate).

- PI Controller: Uses proportional and integral control (eliminates steady-state error).

- PD Controller: Uses proportional and derivative control (faster response, reduced overshoot).

- Full PID Controller: Uses all three terms (best stability and accuracy).

7. Advantages & Disadvantages

✅ Advantages

✔ Simple and widely used

✔ No need for a system model

✔ Works well for many applications

❌ Disadvantages

✖ Requires tuning for each application

✖ Can become unstable if not tuned properly

✖ Not ideal for highly dynamic, nonlinear systems

Leave a Reply